Introduction: PU (Polyurethane) rubber seals are widely recognized for their excellent performance in various sealing applications. This article aims to provide a comprehensive overview of the performance characteristics of PU rubber seals, highlighting their unique attributes and advantages in different industries.

-

Excellent Abrasion Resistance: PU rubber seals exhibit exceptional resistance to abrasion, making them ideal for applications that involve frequent movement or contact with rough surfaces. They can withstand wear and tear, ensuring long-lasting sealing performance even in demanding environments.

-

High Load-Bearing Capacity: PU rubber seals are known for their high load-bearing capacity, making them suitable for applications that require sealing under pressure. They can effectively withstand compressive forces, maintaining their sealing integrity and preventing leakage.

-

Impressive Flexibility and Elasticity: PU rubber seals offer excellent flexibility and elasticity, allowing them to adapt to dynamic conditions and provide reliable sealing performance. They can withstand repetitive deformation without losing their original shape, ensuring a tight and effective seal.

-

Resilience to Various Chemicals and Oils: PU rubber seals exhibit good resistance to a wide range of chemicals, oils, and solvents. They can maintain their sealing properties even when exposed to aggressive substances, providing reliable sealing in chemically challenging environments.

-

Wide Temperature Range: PU rubber seals have a broad temperature operating range, enabling them to maintain their sealing effectiveness in both high and low temperature environments. They can withstand extreme temperature fluctuations without compromising their performance.

-

Excellent Aging and Weathering Resistance: PU rubber seals demonstrate remarkable resistance to aging and weathering, including exposure to UV radiation and harsh environmental conditions. They can retain their sealing properties over an extended period, ensuring consistent performance and longevity.

-

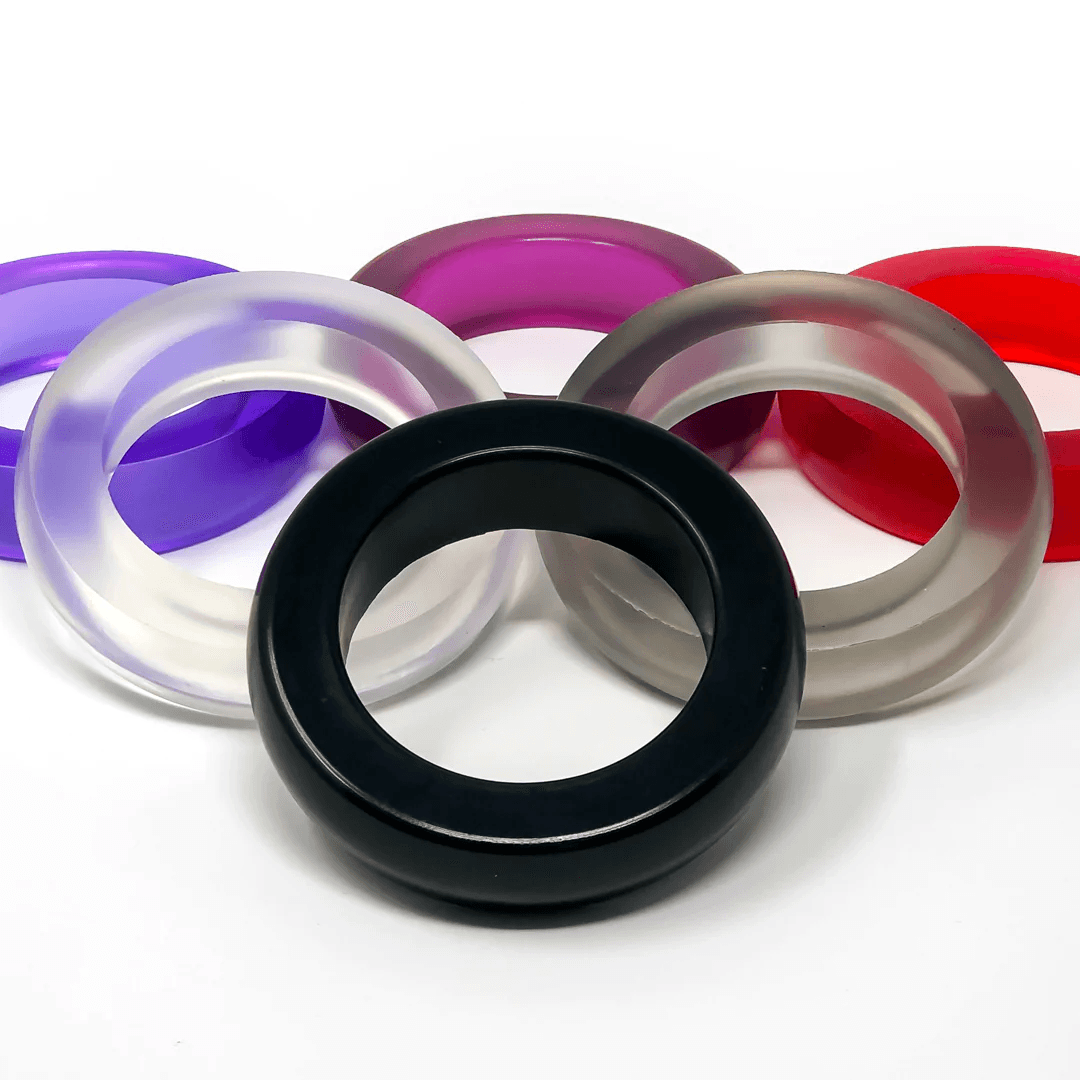

Customizable Solutions: PU rubber seals offer versatility in design and customization. They can be tailored according to specific application requirements, such as size, shape, hardness, and other parameters, to achieve optimal sealing performance and compatibility with different sealing environments.

Conclusion: PU rubber seals are known for their exceptional abrasion resistance, high load-bearing capacity, flexibility, chemical resistance, wide temperature range, and resistance to aging and weathering. These seals are widely utilized in various industries, including automotive, machinery, hydraulics, and more. With their reliable sealing performance and customizable solutions, PU rubber seals provide effective sealing solutions for diverse applications.